“Losses of tens of thousands of yuan per minute of downtime? Fanless industrial PCs guard production lines with zero-failure design — all-aluminum body heat dissipation, military-grade shock resistance, and 10-year maintenance-free operation, freeing high-end manufacturing from downtime anxiety.”

On the production lines of high-end manufacturing, “downtime = burning money” has become a consensus. Precision processing and automated production lines generate tens of thousands of yuan of output value per minute, and the losses caused by equipment failures are incalculable. Now, more and more leading factories are replacing their “industrial brains” with fanless industrial PCs. What makes them so powerful?

- What is a Fanless Industrial PC?

A Fanless Industrial PC is an industrial computer that replaces traditional fan cooling with passive heat dissipation technologies (such as all-aluminum body heat dissipation and heat pipe conduction). It abandons the mechanical fan design, fundamentally solving problems like dust accumulation and fan failure, and is built exclusively for harsh industrial environments.

- A “Must-Have” for Modern Factories: Low Failure Rate & Maintenance-Free Operation

Supreme Stability

Manufacturing production lines require 24/7 continuous operation. Fans in traditional industrial PCs are prone to dust accumulation and jamming, leading to overheating and downtime. The fanless design reduces the failure rate by more than 80%.

Zero Maintenance Costs

No moving parts mean no need for regular cleaning or fan replacement, making it ideal for harsh environments with dust, oil fume, and high humidity (e.g., automobile manufacturing, food processing).

Long Service Life Cycle

Industrial equipment has a long return on investment cycle, and fanless industrial PCs have an average service life of over 10 years, far exceeding traditional models.

Comparison Table of Key Differences Between Fanless Industrial PCs and Traditional Fan-Cooled Industrial PCs

III. Five Core Advantages of the Fanless Design

Ultimate Reliability

No mechanical wear, IP65 protection rating (dustproof and waterproof), and adaptable to wide-temperature operation from -20℃ to 60℃.

Silent & Energy-Efficient

Zero noise and 30% lower power consumption, aligning with the trend of green factories.

Shock & Impact Resistant

All-solid-state structure, passing the MIL-STD-810G military-grade shock resistance test.

Compact & Flexible

Ultra-slim body design saves space and supports wall-mounted/guide rail installation.

Smart Expandability

Supports multiple network ports, serial ports, and PCIe expansion, compatible with the requirements of the Industrial Internet of Things (IIoT).

- Why Are Industrial Panel PCs So Popular? What Are Their Features?

Industrial panel PCs windows 10 have become a powerful tool for intelligent manufacturing, warehousing and logistics, and outdoor operations with their IP65/IP68 protection, wide-temperature operation from -20℃ to 60℃, multi-interface adaptation, and military-grade stability. RCOMPT, with 13 years of technological accumulation, provides scenario-based customized solutions to empower enterprises in efficient digital transformation.

In the wave of intelligent manufacturing, industrial panel PCs are becoming a standard configuration in scenarios such as workshop production lines, outdoor operations, and medical terminals with their characteristics of “stability, reliability, and flexible adaptation”. Why can they replace traditional industrial PCs? And how can they operate continuously and efficiently in extreme environments? Today, we will talk about the reasons for the popularity of industrial panel PCs.

What Makes Industrial Panel PCs a Favorite?

Maxed-Out Hardcore Protection

IP65/IP68 dustproof and waterproof, wide-temperature operation from -20℃ to 60℃, drop and shock resistant — easily handling dusty and oily environments.

Ultra-Long Standby, No Disconnection

Hot-swappable battery + low-power design support 7×24-hour uninterrupted operation, ensuring worry-free battery life for production lines and outdoor operations.

Versatile Interface Compatibility

Multiple serial ports, network ports, and USB expansions for seamless connection with PLCs, barcode scanners, sensors, and all industrial equipment.

Stability & Reliability as the Baseline

Industrial-grade motherboards + fanless heat dissipation with a Mean Time Between Failures (MTBF) of over 50,000 hours.

Scenario-Adaptation Expert with Customized Services

Customizable configurations from 7~21-inch screens, Intel/ARM processors to RFID modules and hot-swappable batteries according to industry needs. Supporting Windows/Linux/Android systems, it seamlessly connects with industrial software such as MES and SCADA, lowering the threshold for enterprises’ digital transformation.

specific requirements industrial panel pc display screen

The display screen of industrial tablet computers has specific requirements. In terms of brightness, to ensure clear display in different lighting environments, the brightness generally needs to reach 400nits or more, and even 1000nits is required in strong light environments. The contrast ratio should be high, usually above 1000:1, to present clear images and text. Color accuracy is also important, as it can accurately reproduce various colors and meet the high color requirements of industrial design, image recognition, and other applications. The screen has good protective performance, with anti glare and anti scratch functions, and the surface hardness generally reaches 3H or above. In addition, the response time should be short to avoid residual images when displaying dynamic images, generally within 20ms.

- Three Core Scenarios Addressing Pain Points

Intelligent Manufacturing

Real-time production line monitoring and equipment fault diagnosis, with touch operation simplifying processes and improving efficiency by more than 30%.

Warehousing & Logistics

RFID/barcode scanning + GPS positioning boost the accuracy of cargo tracking and inventory counting to 99.9%.

Outdoor Operations

On-site data collection for power inspection and petroleum exploration, with sunlight-readable screens and glove touch support for normal use in harsh environments.

Why Choose Industrial Panel PCs Over Commercial Ones?

| Aspect | Industrial Panel PC | Commercial Panel PC |

|---|---|---|

| Service Life | 5-10 years | 2-3 years |

| Protection Rating | IP65/IP68 + wide temperature | Below IP54, normal temperature only |

| Expandability | Supports PCI/PCIe expansion slots | Fixed interfaces, limited expansion |

- RCOMPT Smart Fanless Industrial Panel PCs: Empowering High-End Manufacturing

Guangdong Computer Intelligence Display Co., Ltd. is a national high-tech enterprise with 10 years of deep cultivation in the industry, specializing in the R&D, design, intelligent manufacturing, sales and service of industrial computers, industrial panel PCs and rugged tablet PCs, with a total of 92 authorized patents (including 27 invention patents).

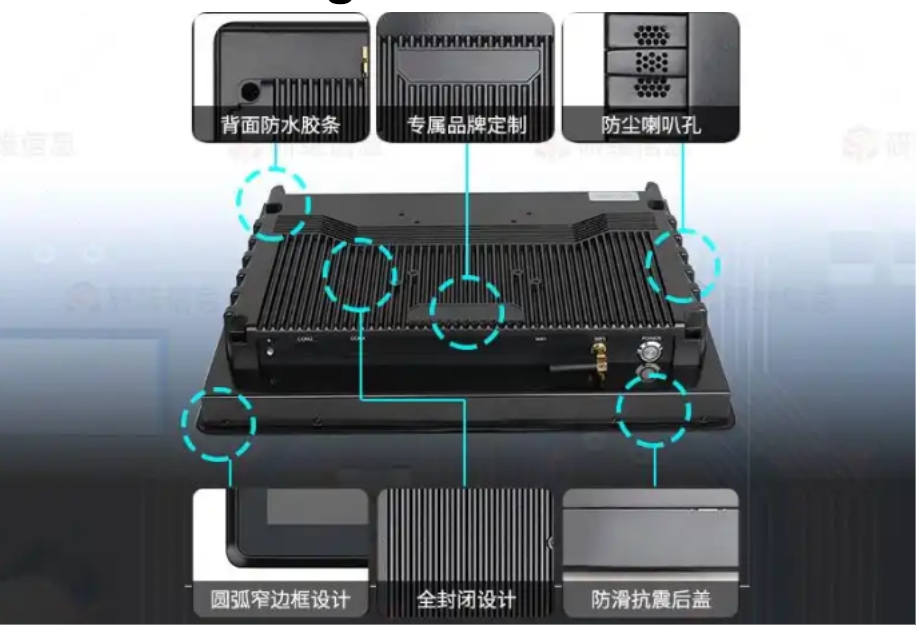

Our smart fanless industrial PCs on gdcompt.com aim for “zero defects” and build differentiated competitiveness with the following features:

Integrated design: IP65 front panel protection, supporting embedded/wall-mounted installation, saving space and adapting to dusty and humid industrial environments.

Fanless and silent: All-aluminum casing for heat dissipation with an MTBF of over 50,000 hours.

Compact with powerful expandability: Supports PCIe/mini-PCIe slots, compatible with independent graphics cards and capture cards.

High-definition touch: Multi-size, 10.1-21.5 inch multi-point capacitive screens, adapted to industrial human-computer interaction scenarios.

Multi-configuration: Supports ARM, Intel 4th-12th Gen Core, Celeron J1900/J6412, N-series N97/N100 and other CPUs.

Flexible expansion: Optional 4G/5G/WiFi modules and PoE power supply, compatible with data collection from PLCs, sensors and other equipment.

OEM customization: BIOS customization, LOGO silk screen printing, customized packaging, etc.