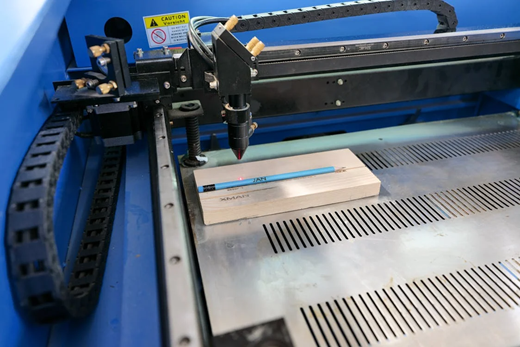

Laser engraving machines are revolutionizing how businesses personalize products, mark parts, and streamline production. With so many models on the market—each promising performance, precision, and power—how do you ensure you’re getting what you need without overpaying? Understanding the laser engraving machine is a key part of that process. From entry-level desktop units to industrial-grade systems, prices vary based on features, power, and intended use. This guide breaks down the key considerations to help you match your requirements with the right laser engraving machine. We’ll explore how to avoid unnecessary upgrades, identify which features truly matter, and assess long-term value rather than just the sticker price.

Here’s How To Choose The Right Laser Engraving Machine Without Overpaying

Define your application clearly

Before browsing specs and comparing prices, get crystal clear about what you’ll be engraving. The material and end use play a significant role in determining the type of machine.

- For wood, leather, acrylic, or paperboard, a CO₂ laser is the best fit.

- For metal, aluminum, brass, or industrial parts, a fiber laser is typically required.

- For heat-sensitive plastics or glass, a UV laser may be ideal.

If your application is niche—like jewelry engraving, electronic PCB marking, or packaging codes, look for industry-specific features. Overpaying often occurs when buyers purchase a more powerful or versatile system than they need.

Match the laser type to your materials

Here’s a quick breakdown of laser types and their ideal uses:

CO₂ Laser:

- Great for organic materials and non-metals

- Affordable entry-level models

- Popular for signage, woodworking, and crafts

Fiber Laser:

- Ideal for metals and industrial applications

- Longer lifespan and low maintenance

- Often used in automotive, tools, electronics, and hardware engraving

UV Laser:

- Perfect for delicate or transparent materials

- Precise but usually more expensive

- Best for plastic, silicon, and glass engraving

Choosing the wrong type may mean you either underperform or waste money on unnecessary capabilities.

Know your required power level

Laser power, measured in watts, affects the speed, depth, and efficiency of the engraving process. Higher wattage generally means faster processing, but it also increases the price.

For example:

- 20W–30W fiber lasers efficiently handle small to medium marking tasks.

- 50W and above are better suited for deep engraving, fast marking, or batch processing.

- CO₂ lasers typically start around 40W for craft-level work and can exceed 100W for industrial needs.

Don’t get drawn into buying a high-wattage machine “just in case”—unless you genuinely need that level of speed or power.

Consider work area size

The work area size determines the maximum size of objects that can be engraved. Bigger isn’t always better—larger beds increase costs and take up more space.

- For pens, tags, jewelry, and small parts, a 100mm x 100mm to 200mm x 200mm area is enough.

- For larger panels, sheets, or signage, look for 300mm x 300mm and above.

Overpaying often happens when businesses purchase large-format machines with unused engraving space. Evaluate your most frequent job size and scale accordingly.

Evaluate build quality and components

A budget-friendly machine may save money upfront, but cheap components can lead to alignment issues, vibration, or overheating.

Check for:

- Sturdy metal chassis (avoid flimsy plastic housings)

- Dust-sealed optics and enclosed beam paths

- High-precision galvo heads for fiber lasers

- Air assist or cooling systems in CO₂ machines

If you’re running the machine daily or in an industrial environment, investing in durable and high-quality parts upfront can prevent long-term repair costs and downtime.

Prioritize reliable software

Even a high-end laser won’t work smoothly without reliable control software. Features to look for include:

- Easy design import (SVG, DXF, AI, etc.)

- Barcode, QR code, and serial number support

- Batch processing tools

- Adjustable engraving parameters

- Compatibility with Windows or other platforms

Machines bundled with proprietary, poorly supported software can slow production and cause frustration. Choose systems with well-documented, regularly updated programs, or third-party compatibility like LightBurn or EZCAD.

Focus on essential features, not gimmicks

Some sellers lure buyers with features that sound advanced but offer little added value for most users. These might include:

- Overpowered wattage for simple materials

- Complex rotary attachments you’ll rarely use

- Auto-focus or vision systems on hobby-level machines

Instead, pay for the features that boost your actual productivity: faster engraving speeds, a more stable build, a straightforward interface, and local support.

Look for local support & warranty

In India, especially, having local service availability is a significant advantage. If your machine needs alignment, replacement optics, or firmware updates, importing support from overseas can be costly and slow.

Choose a brand or supplier that offers:

- On-site installation and demo

- Remote troubleshooting

- Spare parts availability

- Warranty (minimum one year)

- Service contracts or AMCs

The best way to avoid overpaying is to ensure your machine won’t incur hidden costs later due to poor support or unfixable downtime.

Assess upgrade paths & future needs

While overpaying for unused features is a risk, underbuying can result in costly upgrades. Ask yourself:

- Will you expand to new materials within the next 6 to 12 months?

- Will your production volume increase soon?

- Do you anticipate needing ERP/PC integration in the future?

A well-balanced mid-range machine that allows for easy upgrades—such as adding a rotary axis or a larger lens—may be a better investment than replacing a low-end unit too soon.

Compare the total cost of ownership

Don’t just compare upfront machine prices. Include:

- Operating costs (power, maintenance, filters)

- Expected lifespan of components (laser tube life, galvo motors)

- Downtime risk

- Replacement part availability

- Training time and productivity

A slightly higher-priced machine with minimal downtime and better support may deliver greater value over five years than a cheaper unit with recurring issues.

The Final Thoughts

Choosing the right laser engraving machine is about intelligent matching—aligning your specific needs with proven capabilities, not hype. By understanding the material you’ll engrave, the power and area you require, and the real-world support available, you can confidently avoid overpaying. Think of it this way: you’re not just buying a machine; you’re investing in speed, quality, efficiency, and peace of mind. Whether you’re customizing wood signs, marking metal parts, or engraving nameplates, the right decision today means fewer costs and better results tomorrow.